Freight shipping has not always been as efficient and technologically advanced as it is today. Shipping and packaging have undergone significant transformations since its inception.

Shipping cargo can be traced back to the 3rd century B.C. Freight transportation first began in horse-drawn wagons, and the transfer of goods was done locally. As trade began to expand, products were shipped farther and eventually overseas. However, there were no regulations back then, so most items could get lost due to rough sea conditions or stolen from pirates and thieves.

In the 19th century, the railroad network began to expand quickly in the U.S. By 1869, the Transcontinental Railroad was finished. In the late 19th century, railroads were the most dominant mode of transportation. In the 20th century, cities began paving roadways, leading to about 173 billion ton-miles of commercial freight being transported on them by 1950.

Not only has the evolution of freight transportation seen rapid advancements but so has the packaging in which freight is transported.

The Progression of Different Packaging

Paper

Paper packaging is the oldest known form of packaging, created in the 1st and 2nd centuries B.C. in China. The packaging was originally made out of flexible mulberry bark and primarily used to protect food. Papermaking techniques were expanded into Europe, the Middle East, and America. Early forms include flax fibers and old linen, but over time, paper has been made from an array of different sources. Paper originating from wood pulp was finally developed in 1867.

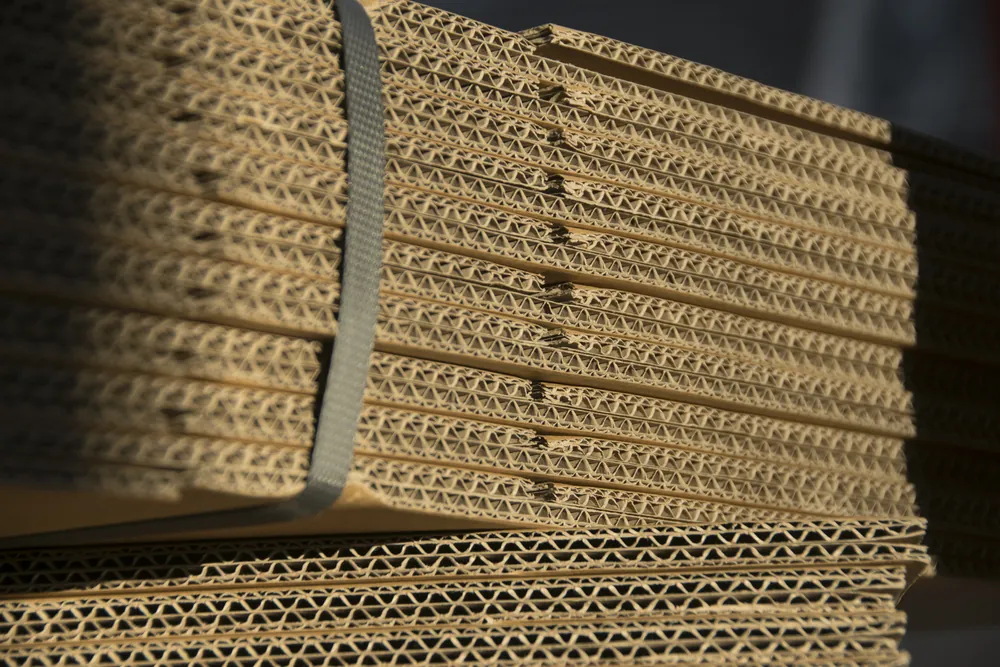

The first commercial cardboard box was made in England in 1817, and by the 1850s, corrugated cardboard had been invented, eventually replacing wooden boxes.

Today, corrugated cardboard boxes are widely used in freight shipping. They are one of the most popular choices for transportation due to their durability and cost-effectiveness. They can be used to ship fragile items and even hazardous materials.

Wood

Wood packaging is the first known source used for shipping purposes. Between the 15th and 18th centuries, wooden crates were mostly used in Europe to transport goods overseas.

Not only were wooden crates reliable because of their sturdiness, but the wood could withstand harsh and salty conditions from ocean voyages. This made wooden crates ideal for shipping for hundreds of years. These crates were used to transport virtually anything until corrugated cardboard replaced it.

Wood is still used today as a sustainable alternative to shipping freight in crates, pallets, or boxes.

Metal

Metal is a form of freight packaging that ultimately transformed the shipping industry. Metal was first discovered as a tin sheet in 1200 A.C. in Bohemia. Over the years, metal tins were used to package things like tobacco, matches and later, food. In 1866, the first metal box was made in the U.S., but they were not commercially available in stores until 1910.

It wasn’t until 1956 that American truck driver Malcolm Mclean invented a transportable storage vessel. Mclean developed the first metal shipping containers, revolutionizing the freight industry. Not long after his invention, shipping containers were standardized and graded. For example, shipping food requires a food-grade container.

Metal shipping containers are widely used today in the shipping industry for their incredible durability and easy transport.

Plastic

The history of plastic began in 1869 when John Wesley Hyatt created the first synthetic polymer. In 1907, Leo Baekeland invented the first fully synthetic plastic, which could be molded into anything. Thus, plastic packaging began.

During WWII, the use of plastic containers began to surge due to war demands. Plastic was cost-effective, versatile, and a sanitary way to store goods.However, it wasn’t until 20 years later that plastic became a product used in freight packaging. Poly mailers are lightweight, waterproof, stackable, and sturdy plastic mailing bags. In freight shipping, poly mailers are used for products already in sturdy packaging.

Cellophane is another form of plastic used in freight shipping. It was invented in 1924 but wasn’t commercially used until the late 50s and early 60s. Cellophane is wrapped around packages to help keep moisture out and prevent damage.

Cushioning In Packages

Cushion methods in freight packaging have also evolved. In the earlier stages of shipping, hay, sawdust, cloth, and burlap were used to protect the items inside a crate or box. In more recent years, foam, bubble wrap, and packing peanuts have been used for additional protection.

What Role Have Truck Drivers And Warehouse Workers Played?

Believe it or not, truck drivers and warehouse workers play a crucial role in the evolution of freight packaging. During handling and transit, drivers and workers report instances of product damage and other issues that arise. This can lead to innovations in packaging.

Some of these innovations include ergonomic designs that make handling heavy packages easier. The need for secure and stable stacking of freight has led to better palletization and the use of strapping and shrink wrap to secure loads.

The continuous feedback of these workers in the freight industry helps to continue improving and advancing ways of packaging.

The Future Of Freight Packaging

Today, innovations in freight packaging are constantly being proposed. Recently, various improvements in packaging quality, known as smart packaging, have occurred. Advancements in smart packaging began in the 2000s and 2010s. According to Future Market Insights (FMI), the market aims to reach $38.3 billion by 2033.

Smart packaging adds electronic devices to increase its functionality. This includes radio frequency identification devices (RFID) to monitor the conditions of the shipments and give information about their tracking status. The packaging is also equipped with antimicrobial agents and moisture absorbers to extends shelf life and maintain overall quality of the product inside.

QR codes are also added to the packages to give the receiver additional information and enhance consumer engagement. Innovative packaging enhances consumer experience and helps companies improve inventory management and the quality of their products.

The evolution of freight packaging, from wooden crates to corrugated cardboard and plastic, proves the significant advancements made over time. Companies are continuously finding new and innovative ways to create more durable, eco-friendly, and intelligent packaging.