Shipping Roll Bars & Cages

Shipping roll bars/cages involves transporting safety components designed to protect vehicle occupants in the event of a rollover or collision. These sturdy structures, typically made of materials like steel or aluminum, are crucial for enhancing vehicle safety. During shipping, proper handling and protection is essential to maintain the integrity and effectiveness of these safety features.

Racing enthusiasts and professionals understand that the correct roll bar/cage system can make all the difference on the track by staying up-to-date with safety standards, embracing technological advancements, and prioritizing packaging and shipping quality.

While the racing community continues to push boundaries, it sets new records and makes the sport safer and more competitive than ever; FreightCenter is here to deliver those same expectations.

Preparing Roll Bars / Cages for Shipping

Shipping roll bars/cages safely begin with thorough preparation. These essential safety components must be in optimal condition upon arrival. Here’s how to get them ready:

Inspection and Quality Control

Before shipping, inspecting the roll bars/cages for any signs of damage, wear, or rust. Ensure that all welds and joints are secure and that there are no cracks or weak spots.

Quality control is vital to guarantee structural integrity, especially in the competitive field when every inch matters.

Protective Coatings and Finishes

These bars/cages are most often made of steel or aluminum. Apply protective coatings or finishes to prevent corrosion during transit. Rust can compromise the structural strength, so safeguarding against it is ideal.

Labeling and Documentation

Proper labeling and documentation are crucial. Marking the packages as “Fragile” or “Handle with Care.” Provide detailed documentation to ensure compliance with shipping regulations, safely guard your equipment, and track your shipment.

Partnering with Experienced Shipping Services

Collaborate with FreightCenter, which has experience handling delicate and specialized cargo like roll bars/cages. They understand the importance of secure packaging and proper handling.

Packaging Considerations

Securely package the shipment to prevent shifting, impacts, or damage. Custom crates or specially designed packaging may be necessary to ensure they reach their destination in pristine condition.

Shipping Roll Bars / Cages: Challenges and Solutions

Shipping roll bars can pose unique challenges due to their size, shape, and importance for safety. Here’s how to navigate these challenges and find practical solutions:

Challenges of Transporting Roll Bars

These shipments are often large and unwieldy, making them difficult to transport. Their shape and dimensions may not fit standard shipping containers, requiring custom solutions.

Packaging Strategies

Custom crates and specialized packaging materials are often necessary to secure shipments during transit. Like steps to ensure the density of cargo, these strategies protect them from damage caused by vibrations and shocks during transport.

Freight Options

Consider different FreightCenter options, such as ground, air, or sea shipping, depending on the urgency and distance of your shipment. Shipments may require dedicated transport due to their size.

International Shipping

You’ll encounter customs and regulatory challenges when shipping roll bars/cages internationally. Ensure compliance with the specific requirements of the destination country to avoid delays, issues, or mishaps.

Tracking and Monitoring

Use tracking and monitoring systems to monitor your shipment’s progress, helping ensure that shipments are on schedule and arrive at their destination as planned.

Shipping roll bars/cages demands careful planning and consideration of these challenges. Working with experienced shipping professionals who understand the unique requirements of these safety components is vital to a thriving shipping process and work management when it comes to racing and competitions.

Award-Winning Service, Trusted by Shippers Everywhere!

- 2021, 2017 & 2016 Food Logistics’ Top Green Providers

- 2021 & 2018 Supply & Demand Chain Executives’ Pros to Know: Matthew Brosious

- 2020 & 2019 Top Food Logistics’ 3PL & Cold Storage Provider Award

- 2020 & 2019 Business Observer’s Top 500 Companies on the Gulf Coast

- 2020 & 2017 SmartWay® Transport Partner

- 2020 & 2017 Food Logistics’ Champions: Rock Stars of the Supply Chain

- 2020 Best of Palm Harbor Awards for Local Businesses

- 2017 Green Supply Chain Award from Supply & Demand Chain Executive

- 2017 Tampa Bay Business Journal Heroes at Work

- 2016, 2015, & 2012 Food Logistics Top 100 Software and Technology Providers

- 2013 Tampa Bay Business 100 by Tampa Bay Business Journal

- 2013 Top 100 Great Supply Chain Partners by SupplyChainBrain

- 2012 TIA Samaritan Award Honorable Mention

- 2012, 2011 & 2010 TBBJ Fast 50 Recipient

- 2013, 2011, & 2010 Diversity Business Top Businesses

Know What Your Shipping

It’s a common misconception that standard U.S. road cars’ roll bars and roll cages are illegal. While they aren’t against the law, they’re rarely used in everyday vehicles due to practicality and safety concerns. On occasion, being in convertibles and removable tops such as JEEP to meet safety standards, roll bars provide rollover protection.

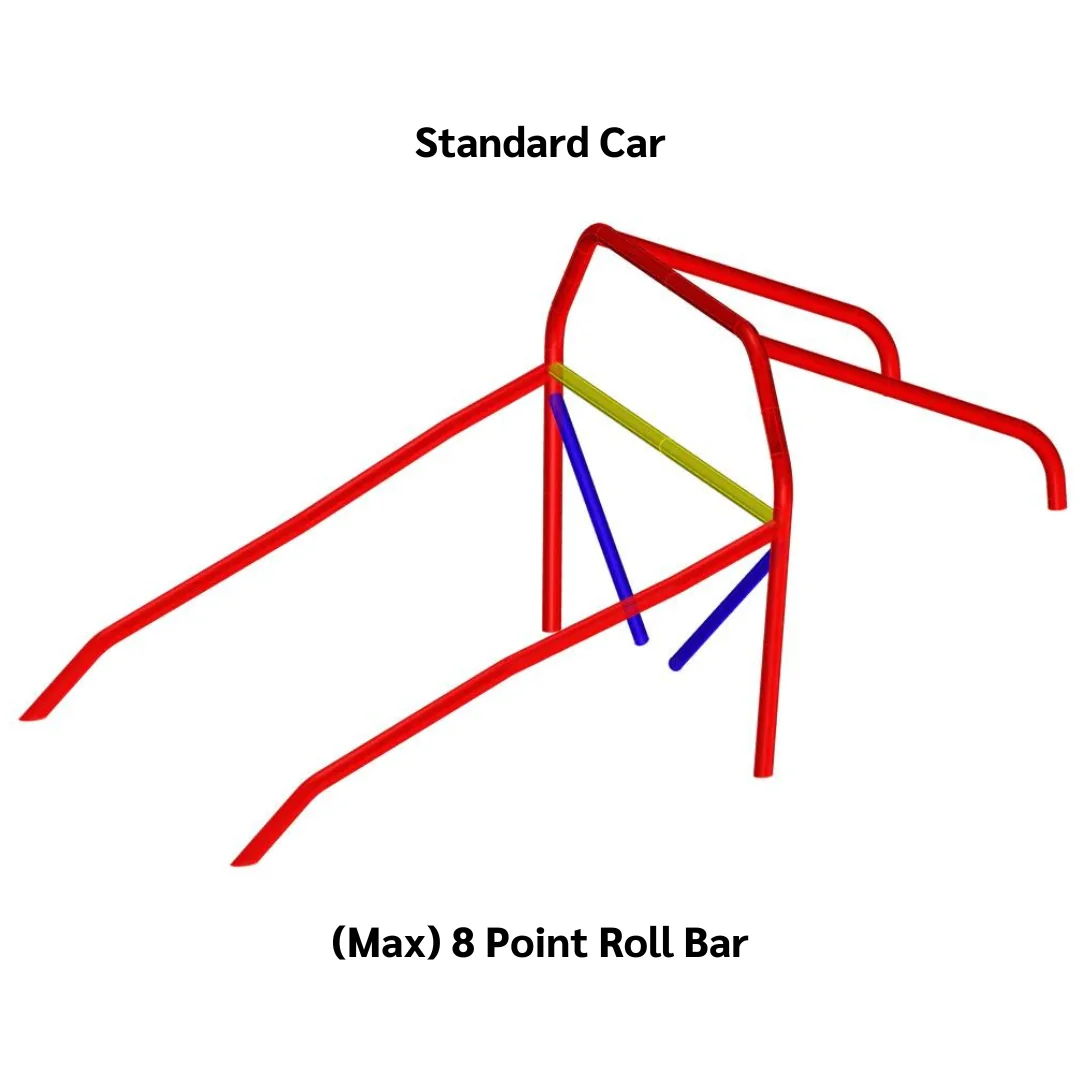

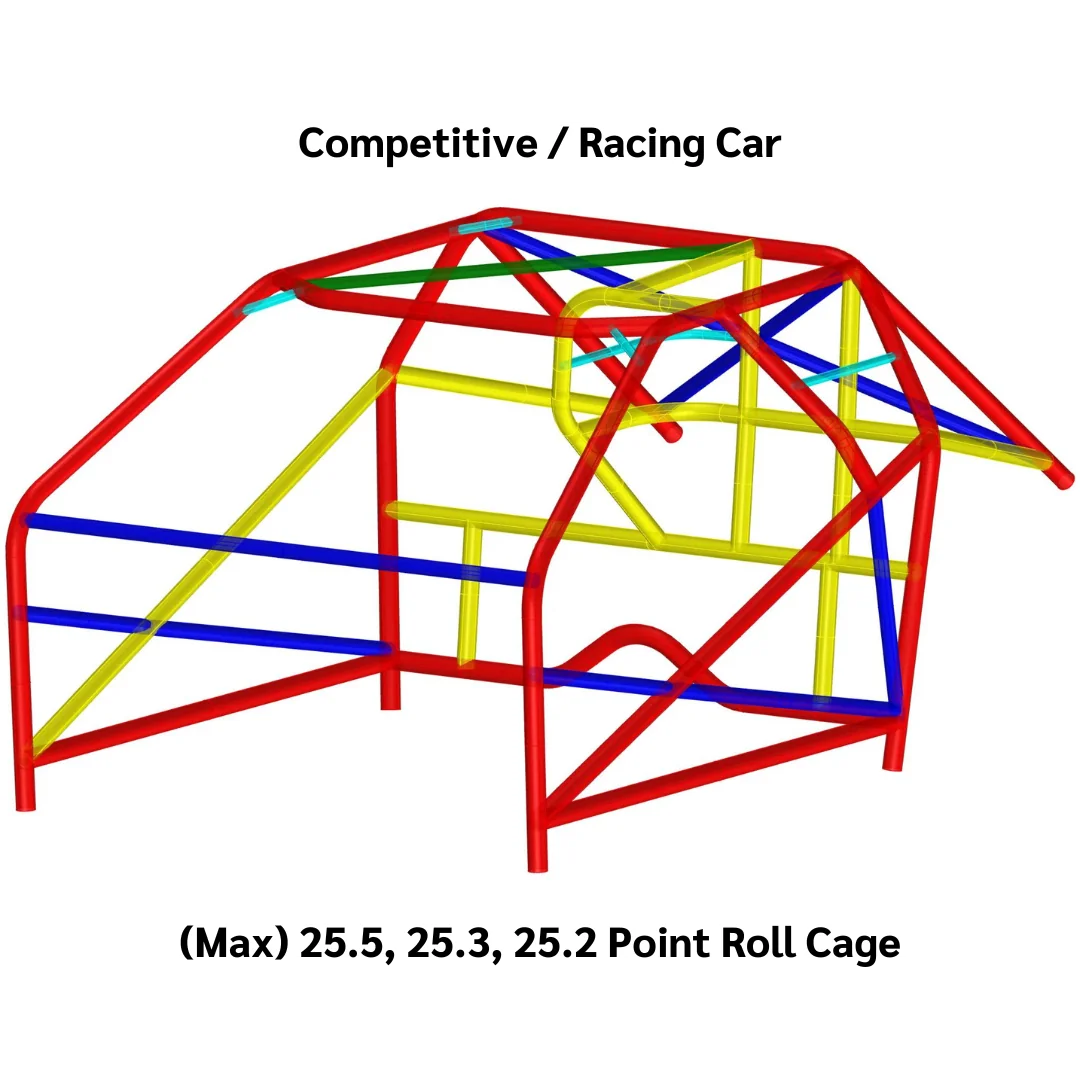

In contrast, full roll cages, with ratings like 8-point for roll bars and higher ratings like 25.5, 25.3, and 25.2 for roll cages, are reserved for racing cars to ensure safety under extreme motorsport conditions.

Specific considerations differentiate their use in racing vehicles from those in normal road cars. A Roll “CAGE” differs from a “BAR” in that it will include some form of overhead tubing structure that extends forward on both sides from the main hoop along the roof line to the A-Pillars, across the roof and windshield line and down to the floor, inner rocker, or frame of your car.

Remember when we’re speaking about a “CAGE” that the door bars on a cage run into the base of the A-Pillar bars and are not considered attachment “points.” The A-Pillar bars are now your forward points, replacing door bars on a Roll” BAR” as two points.

Standard Cars

Roll Bars

Roll bars, specifically roll hoops or single hoop bars, are sometimes used in standard road cars, especially in convertible models, to enhance rollover protection. In these cases, car manufacturers such as Jeep typically design and install them to meet safety standards and regulations. Roll bars are engineered to protect passengers in a rollover accident.

Roll “BARS” generally have a main hoop, the main bar, or the starting point of a Bar or Cage install located behind your head. Being shaped like a giant upside-down U is your first 2 points. Harness bars run from the driver to the passenger side behind your front seats, and you would typically attach your safety harness shoulder straps to this bar.

To be NHRA legal, this bar is required and can NOT be removable.

Roll Bar Point Size

-4 Point

not recognized by NHRA, would have two bars running into the back of the car to support the main hoop from folding over. This will help with some chassis structure and roll-over protection. It is your best option if you use your car on the street with NO rear passengers.

-6 Point

is NHRA legal in a hard top car from 11.49 to 10.00 qtr mile times at the time of this writing and would add a driver and passenger side diagonal door bar to a 4pt bar.

-8 Point

It is the same as a 6pt with the addition of two (NHRA D bars), commonly called kickers by many. NHRA does not require the addition of kickers to a roll bar and doesn’t allow you to run any faster than a 6pt ba.

Kickers add additional cage and chassis structure, especially when attached to frame connectors or undercarriage tubular structure in a unibody or full-frame car.

Roll Cages

On the other hand, full roll cages are generally not used in standard passenger cars due to several practical reasons collectively; these factors make roll bars/cages more suitable for racing vehicles, where their safety benefits outweigh these practical limitations:

Space and Comfort

Roll cages occupy a significant amount of space within the cabin, which can drastically reduce passenger seating and comfort. This makes them impractical for everyday use.

Visibility and Accessibility

Roll cages can obstruct driver visibility with their complex network of bars and supports. This can significantly block the driver’s field of vision and make it difficult to enter and exit the vehicle, making one squeeze or tuck their body around the metal bars.

Safety Concerns

Roll cages, if not professionally installed and integrated with the vehicle’s structure, can pose safety risks, including the possibility of injury to occupants in non-racing scenarios. They can also interfere with the deployment of airbags and other concerns about head injuries

Due to having exposed metal throughout the inside of the vehicle, if an accident were to occur, why they do recommend helmets when in use of a roll cage.

Competitive & Racing Cars

Roll bars are rarely seen in competitive / racing cars. Roll cages are most common, where safety standards and requirements significantly differ from those for standard road cars. In motorsport, roll cages are essential for protecting drivers in high-speed racing conditions, where the risk of rollovers and collisions is much greater.

These roll cages are designed, built, and installed to meet specific safety standards set by racing organizations such as the Fédération Internationale de l’Automobile (FIA) and the National Auto Sport Association (NASA).

Roll Cage Point Size

-6 Point

Is NHRA legal from 9.99 to 8.50 in a full perimeter frame car (for example, GM A & G Bodies) where the frame of a car runs around the perimeter of your car, next to your inner rockers, and outside of your hip. A 6pt cage is a cage as described above without NHRA D bars, also known as “kicker” bars.

-8 Point

This is the minimum required to meet sub 9.99 rules on all cars that are NOT perimeter frame cars. It is the same as a 6 pt cage with the addition of the two NHRA D/kicker bars that you will tie into your sub-frame connectors, inboard rails, or some other under-carriage tubular structure, depending on what car you have.

This is the minimum cage required for Mustangs, F-Bodies, X-Bodies, Tri-5 cars, and most other cars and trucks.

-10 Point

This is the same as the 8pt with a rear X bar setup and the two usual back bars that come with your cage kit. All of the X’s on our kits require final fitting by the installer as not everyone wants to install their X in the same way. An X is an excellent way to add a large chassis structure and roll-over protection to any car cage.

Typically, it is only used in cars with no rear seats.

-12 Point

A 12pt is still legal to 8.50, but comes with a pair of bars that extend through your firewall up to the front area of your car’s frame, typically somewhere forward of your front tire and a little back from your radiator support. These add extra structure and are sometimes used for front engine plate mounting.

-25.5, 25.3, 25.2 Point

Are all sub 8.50 or over 180mph (qtr. mile time) cages? That is a whole other topic in itself. If you are looking for info about a 25._anything cert cage, we’d recommend checking out the SFI foundations website, giving them a holler, and ordering the spec book pertaining to your needs.

To create value for our customers by delivering customized shipping solutions that meet their unique needs and to fulfill shipping demands from simple to complex with expertise, guidance and ingenuity.

Rail shipping is a cost-effective and environmentally friendly transportation method that utilizes trains to move goods over long distances. It's known for its efficiency in handling large volumes of cargo, making it a sustainable and economical choice for businesses seeking reliable freight transport options.

Expedited shipping is a premium service designed to meet urgent delivery needs. It prioritizes speed and quick turnaround, ensuring that packages or goods reach their destination faster than standard shipping options. Expedited shipping is the go-to choice when time-sensitive deliveries are essential, providing businesses and individuals with reliable and prompt service for critical shipments.

White glove shipping is a premium service that goes beyond standard delivery, offering meticulous handling, specialized packaging, and in-home setup or installation for valuable or delicate items, ensuring a seamless and hassle-free experience for customers.

Less than truckload (LTL) shipping is a smart logistics solution for businesses with smaller shipments. It combines multiple smaller shipments into a single truckload, optimizing space and reducing costs. LTL shipping offers affordability and efficiency while ensuring timely delivery, making it an ideal choice for companies looking to save on transportation expenses without compromising on service quality.

Why Choose FreightCenter?

Expert Handling

FreightCenter specializes in transporting specialized cargo, ensuring that your roll bars and cages are shipped with the utmost care and expertise during every stage of the shipping process.

Compliance and Documentation

We can assist with the necessary documentation, ensuring that your cargo complies with safety and regulatory standards, particularly if you’re shipping internationally.

Timely Delivery

FreightWeight’s experience and logistics network enable them to provide reliable and officiant delivery services, ensuring that your roll bars and cages reach their destination when needed.

Customized Solutions

FreightCenter can tailor shipping solutions to meet the unique requirements of roll bars and cages, including secure packaging, specialized crating, and appropriate handling methods to ensure safe transit.

Cost-Effective Options

FreightWeight can offer cost-effective shipping solutions by optimizing routes, consolidating shipments, and leveraging their industry relationships to secure competitive shipping rates.

Peace of Mind

Entrusting your valuable cargo to a professional shipping company like FreightWeight provides peace of mind, knowing that your roll bars and cages will arrive safely and on time, allowing you to focus on other aspects of your racing or automotive project.

Roll bars and cages are non-negotiable when it comes to the safety and performance of racing vehicles. Ensuring these critical components reach their destination safely and on time is a top priority for racing companies, auto shops, and enthusiasts alike.

That’s where FreightCenter is the go-to shipping solution for the racing community, enthusiasts, and all in between.

Regarding shipping the bars and cages, FreightCenter is the trusted partner you need. Their experience, customized solutions, compliance expertise, and commitment to timely and cost-effective delivery make them the top choice for racing companies, auto shops, and racing enthusiasts.

With FreightCenter, you’re not just shipping; you’re ensuring your hobbies or racing endeavors’ safety and a competitive edge.

Thousands of businesses trust FreightCenter to move their freight faster, smarter, and cheaper! From unbeatable rates to top-notch service, our customers are raving about their shipping success.

See why they keep coming back!

Roll Bars / Cages FAQs

Q. How should I prepare roll cages for shipping?

A. Before shipping, inspect the roll cages for damage, apply protective coatings to prevent corrosion, and securely package them to avoid shifting during transit.

Q. What’s the best way to package roll cages for safe shipping?

A. Roll cages should be securely crated or packaged to prevent damage. Customized packaging solutions are often necessary to ensure they arrive in good condition.

Q. Can I ship roll cages internationally?

A. Yes, roll cages can be shipped internationally, but it’s essential to comply with the specific regulations and requirements of the destination country.

Q. What shipping options are available for roll cages?

A. Depending on your needs, you can choose from various shipping options, including ground, air, or sea freight. The choice often depends on the distance and urgency of your shipment.

Q. How can I track my roll cage shipment during transit?

A. Most shipping companies offer tracking services. You’ll receive a tracking number to monitor the progress of your shipment and ensure it reaches its destination as planned.

Q. Are there any restrictions or safety regulations for shipping roll cages?

A. While roll cages are not generally restricted, adhering to safety regulations and securing them properly to prevent damage during transportation is essential.

Q. What should I do if my roll cages arrive damaged or lost during shipping?

A. Contact your shipping company immediately in the rare event of damage or loss. They will guide you through the claims process and work to resolve the issue promptly.