Milling Machines

Expert Shipping for Every Milling Machine Move

Unlock the power of precision with our milling machine shipping! From heavy-duty industrial giants to sleek workshop essentials, we deliver machinery that fuels innovation. Explore our seamless shipping solutions and elevate your manufacturing prowess today!

What to Expect When Shipping Milling Machines

Milling machines are high-value, weighty, and sensitive to shock and moisture, making them a shipping challenge. Whether you’re moving a vertical mill, horizontal mill, or CNC machine, this guide will walk you through every detail of the shipping process. From packaging tips to freight mode selection and how FreightCenter ensures a safe, compliant move.

Thousands of businesses trust FreightCenter to move their freight faster, smarter, and cheaper! From unbeatable rates to top-notch service, our customers are raving about their shipping success.

See why they keep coming back!

Award-Winning Service, Trusted by Shippers Everywhere!

- 2021, 2017 & 2016 Food Logistics’ Top Green Providers

- 2021 & 2018 Supply & Demand Chain Executives’ Pros to Know: Matthew Brosious

- 2020 & 2019 Top Food Logistics’ 3PL & Cold Storage Provider Award

- 2020 & 2019 Business Observer’s Top 500 Companies on the Gulf Coast

- 2020 & 2017 SmartWay® Transport Partner

- 2020 & 2017 Food Logistics’ Champions: Rock Stars of the Supply Chain

- 2020 Best of Palm Harbor Awards for Local Businesses

- 2017 Green Supply Chain Award from Supply & Demand Chain Executive

- 2017 Tampa Bay Business Journal Heroes at Work

- 2016, 2015, & 2012 Food Logistics Top 100 Software and Technology Providers

- 2013 Tampa Bay Business 100 by Tampa Bay Business Journal

- 2013 Top 100 Great Supply Chain Partners by SupplyChainBrain

- 2012 TIA Samaritan Award Honorable Mention

- 2012, 2011 & 2010 TBBJ Fast 50 Recipient

- 2013, 2011, & 2010 Diversity Business Top Businesses

Why Choose FreightCenter for Shipping Milling Machines?

Whether you found a great deal on a milling machine on Craigslist, just sold one on eBay, or are relocating your machine shop, we can help you move down the street or across the country. FreightCenter acts like your shipping department, offering the following services:

- Freight Rate Calculation- Explore available rates and how FreightCenter can make your shipment convenient and cost-effective.

- Flatbed, step-deck, RGN, and covered transport – To secure and protect your machine.

- Loading of machinery – Lifting and loading machine at the point of origin.

- Delivery to the site – Transporting your machine safely and at the best rate.

- Storage and bonded warehousing – FreightCenter agents can assist in facilitating this add-on service.

Shipping Conventional Milling Machines

If you are shipping a conventional milling machine, it is important to properly prepare it for shipping to prevent any damage from occurring.

Take accurate measurements- Determine size, weight, and dimensions. Be sure to keep records of the measurements. Your freight agent will require you to provide this information for your shipping and logistics services.

Clean/Secure Machine- Ensure the products are free of debris, dirt, and contamination. Then identify any delicate parts that need protection, and wrap them with bubble wrap or foam. It is also important to secure any moving parts/accessories, as this will prevent unnecessary movement during transit.

Disassemble Machine – Smaller parts might be easier to ship; however, the milling machine parts could weigh between 200 and 700 pounds. (Before taking your machine apart, be sure you can put it back together!) The spindle heads and table components are usually easily disassembled, which helps reduce the overall size and weight, as well as the handles and cranks. Remove any applicable parts and place them in a wooden box bolted to the pallet for protection. Remember to label these removable components to keep track of them for reassembly.

Crating/Packaging- Milling machinery should be packaged using sturdy wooden crates or on a correctly sized pallet. Use materials that provide adequate padding, cushioning, and bracing to prevent movement. This will prevent the machines from shocks and vibrations during transit. Reinforcing the packaging may be necessary to accommodate the machine’s size and weight.

Find or make a pallet – Find a pallet or build one by using these step-by-step instructions. Once your pallet is made, bolt your machine to the pallet. This will prevent the risk of your machine falling off the pallet.

Shrink wrap the entire pallet – Make sure to wrap the entire package to help secure the machine to the pallet. Ratchet straps may also be used to secure the milling machine to a pallet.

PRO TIP: Crate your freight & save some money! Transporting unpackaged machinery can be very costly. Box, crate, or palletize your freight shipment to save up to 50% or more on shipping costs. Need help packaging your furniture, office systems, or machinery? Talk to your FreightCenter Agent about professional packaging options at an additional cost.

CNC Milling Machine Shipping

Due to CNC milling machines’ size, weight, and sophistication, special freight shipping considerations and over-size shipping will likely be required. FreightCenter can point you in the right direction in choosing a provider to meet those needs.

Possible accommodations for these massive but delicate machines:

- Forklift loading and unloading, step decks, or drop deck trailers

- Specialized equipment or handlers:

- Lowboys and cranes, compact forklifts

- Flat and covered transport

- Air ride and tarped trailers

- Moving parts and electrical components must be protected and stabilized

- Blanket-wrap – Wrapping thick blankets around your machine to cover and cushion it during shipment to prevent damage

- Banding straps – Help secure the machine to the pallet

- Loading and offloading must be considered.

- Machine positioning, assembly, and installation

While milling machines come in different shapes and sizes, all require special care during transportation. Whether your machine is 500 or 5000 pounds, moving it can be difficult without the proper equipment, truck, and experience. We’ll help you determine if your milling machine will need to be shipped using less-than-truckload (LTL) or truckload freight (TL). Make sure to provide us with the following information for accurate quotes:

- What type of milling machine are you shipping?

- Is delivery or pickup in a residential area?

- Will a lift gate be needed at either location?

- How much does your freight weigh?

Miscalculating the weight for items of this size can result in monetary consequences, such as billing adjustments, which can easily be avoided by ensuring you measure everything properly before shipping. With hundreds of vetted carriers servicing local, regional, national, and cross-border markets, FreightCenter can find the logistics best suited for your machine transport needs. Let us help get your milling machine safely to its destination. For questions, answers, and custom freight quotes, speak to one of our agents by calling us at 800.716.7608.

We understand that milling machines aren’t just freight they’re precision investments central to your operations. Whether you're shipping a manual mill across state lines or coordinating the delivery of multiple CNC units to a production facility, our team acts as an extension of yours. We combine industry-specific knowledge, a national network of carriers, and custom logistics solutions to get your equipment delivered safely, on time, and on budget.

Shipping a small benchtop mill or just the parts? FreightCenter's LTL services allow you to share truck space with other shippers while receiving expert handling. We’ll match your load with carriers who know how to move machine tools, ensuring proper bracing, labeling, and handling instructions are followed.

When you’re moving a full-size milling machine or coordinating multiple units, full truckload (FTL) is the way to go. We secure dry vans, flatbeds, or step-decks based on your machine's size and requirements. You’ll receive dedicated truck space with fewer stops, reduced handling, and more control over delivery windows.

Need to get a mill to a facility before a production deadline? FreightCenter offers expedited shipping options with team drivers, direct routes, and real-time updates. Our logistics team prioritizes your shipment to ensure it moves fast without compromising safety.

Not every milling machine fits in a box and not every carrier can handle them properly. That’s where FreightCenter’s specialized freight services come in. From securing rigging and crane loading to arranging white-glove service or international export, we handle the heavy lifting. We coordinate with specialized equipment carriers who understand the weight distribution, securing, and transit protections required for safe delivery.

Ready to Ship a Milling Machine?

Let FreightCenter handle the logistics while you focus on what matters most—your business. Get a free quote online or call (800) 716-7608 to talk with a freight expert today.

Milling Machine Shipping FAQ

Q. How do I ship a milling machine safely?

To ship a milling machine, it should be drained of fluids, partially disassembled if possible, securely wrapped, and crated or palletized. FreightCenter helps coordinate packaging, carrier selection, and transit logistics to protect your machine every step of the way.

Q. What’s the best freight mode for shipping a milling machine?

Most milling machines require Full Truckload or Flatbed freight due to their size and weight. Smaller manual mills may qualify for LTL if crated correctly. FreightCenter matches you with the right mode for efficiency and safety.

Q. How much does it cost to ship a milling machine?

Shipping costs typically range from $500 to $3,000+, depending on the machine’s size, weight, distance, freight class, and accessorial needs. FreightCenter provides instant quotes from top carriers to find the best rate.

Q. Do I need a custom crate to ship a milling machine?

While not always required, custom crating offers the best protection, especially for CNC models. FreightCenter can connect you with crating professionals for heavy or delicate machinery.

Q. Can I ship a milling machine internationally?

Yes. FreightCenter offers international freight services, including documentation support, customs coordination, and carrier matching for ocean or air freight options.

Q. What documents are required to ship a milling machine?

You’ll typically need a Bill of Lading (BOL), packing list, and in some cases, export documentation or customs forms. Our team helps prepare and review these documents with you.

Q. How do I calculate the freight class for a milling machine?

Freight class is based on density, size, and packaging method. Most milling machines fall between classes 85 and 125. Use FreightCenter’s Freight Class Calculator or ask an expert for help.

Q. How long does it take to ship a milling machine?

Transit times range from 2 to 7 business days for domestic freight. Expedited shipping is available for time-sensitive deliveries. We help you choose the best carrier based on your schedule.

Q. What accessorial services might I need?

Depending on your location, you may need liftgate service, limited access delivery, or inside delivery. FreightCenter helps identify and book these add-ons during scheduling.

Q. Can I track my milling machine during shipment?

Yes! FreightCenter offers real-time tracking on all shipments. You’ll receive updates and direct access to your carrier’s tracking interface.

Q. Do I need to drain fluids before shipping a milling machine?

Yes, for safety and compliance, all fluids such as coolant or oil should be drained. This reduces spill risk and ensures regulatory compliance.

Q. Is shipping insurance available for milling machines?

Absolutely. We highly recommend adding freight insurance, especially for CNC machines or custom builds. FreightCenter offers multiple coverage options to protect your investment.

Q. What size trucks are used for shipping milling machines?

We utilize flatbeds, step-decks, and RGNs for larger machines. Smaller mills may ship in dry vans via LTL. The right truck is chosen based on your machine’s specs.

Q. Can I ship multiple milling machines at once?

Yes. FreightCenter regularly handles multi-unit shipments for manufacturers, resellers, and training centers. We’ll help consolidate loads to reduce cost and complexity.

Q. Why should I use FreightCenter to ship a milling machine?

With over 25 years of experience, access to 50+ carriers, and deep expertise in industrial equipment shipping, FreightCenter offers tailored, transparent, and cost-effective solutions. We don’t just quote, we become your shipping partner.

Three Super Interesting Facts about Milling Machines

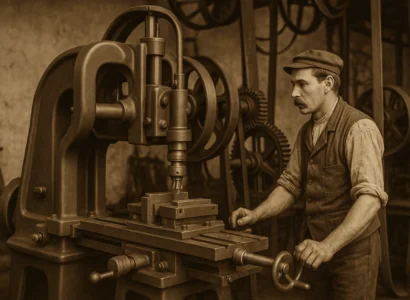

Milling Machines Date Back to the 1800s

The first milling machines were developed in the early 19th century, changing the game for part production. They allowed machinists to shape metal with precision, paving the way for mass production in industries like automotive, defense, and aerospace.

CNC Milling Machines Can Operate 24/7 with Near-Zero Human Input

Modern Computer Numerical Control (CNC) mills use programmed instructions to cut, drill, and carve components around the clock. Many factories now run "lights-out" operations—meaning the machines work overnight without supervision.

Some Milling Machines Weigh Over 30,000 Pounds

Industrial-grade vertical and horizontal milling machines can be massive—requiring special foundations to anchor them during operation. Their extreme weight also means specialized transport like flatbeds or RGNs is often necessary for safe freight shipping.