Pallet Shipping

Ship smarter with fast, affordable, and secure pallet shipping solutions. Get instant quotes, track your freight, and ensure safe delivery every time.

Pallet Shipping: The Smart Solution for Secure and Efficient Freight Transport

Pallet shipping is a cost-effective and reliable method for transporting goods, widely used across retail, manufacturing, and e-commerce industries. By consolidating products onto sturdy platforms like wood or plastic pallets, businesses can maximize space, reduce handling time, and ensure safe delivery. Whether shipping locally, nationally, or internationally, using pallets streamlines logistics and minimizes the risk of damage in transit.

With pallet shipping, companies benefit from flexibility and scalability, whether moving a small Less-than-Truckload (LTL) shipment or a Full Truckload (FTL) of goods. The right pallet size and type are crucial in optimizing freight costs and ensuring smooth handling throughout the supply chain. Businesses can improve operational efficiency and enhance customer satisfaction by understanding how palletized freight works and choosing the best shipping solutions.

Explore how pallet shipping services can elevate your logistics strategy by simplifying complex shipments and lowering costs. Whether new to palletized freight or looking to improve your shipping process, this guide provides everything you need to know to list shipping solutions to meet your business needs.

Thousands of businesses trust FreightCenter to move their freight faster, smarter, and cheaper! From unbeatable rates to top-notch service, our customers are raving about their shipping success.

See why they keep coming back!

Award-Winning Service, Trusted by Shippers Everywhere!

- 2021, 2017 & 2016 Food Logistics’ Top Green Providers

- 2021 & 2018 Supply & Demand Chain Executives’ Pros to Know: Matthew Brosious

- 2020 & 2019 Top Food Logistics’ 3PL & Cold Storage Provider Award

- 2020 & 2019 Business Observer’s Top 500 Companies on the Gulf Coast

- 2020 & 2017 SmartWay® Transport Partner

- 2020 & 2017 Food Logistics’ Champions: Rock Stars of the Supply Chain

- 2020 Best of Palm Harbor Awards for Local Businesses

- 2017 Green Supply Chain Award from Supply & Demand Chain Executive

- 2017 Tampa Bay Business Journal Heroes at Work

- 2016, 2015, & 2012 Food Logistics Top 100 Software and Technology Providers

- 2013 Tampa Bay Business 100 by Tampa Bay Business Journal

- 2013 Top 100 Great Supply Chain Partners by SupplyChainBrain

- 2012 TIA Samaritan Award Honorable Mention

- 2012, 2011 & 2010 TBBJ Fast 50 Recipient

- 2013, 2011, & 2010 Diversity Business Top Businesses

Advantages of Shipping by Pallet – Optimize Your Freight Shipping with Palletized Solutions

Enhanced Protection for Your Freight: Pallet shipping provides secure packaging by keeping goods organized and minimizing movement during transit. Pallets reduce the risk of damage, especially for fragile items and heavy freight, ensuring your shipment arrives safely.

Streamlined Handling for Faster Operations: Palletized freight simplifies loading and unloading with forklifts or pallet jacks, decreasing manual labor. This speeds up shipping processes at warehouses, distribution centers, and shipping docks, improving efficiency and cutting downtime.

Cost-Effective Pallet Shipping Rates: Consolidating multiple packages onto one pallet lowers shipping costs by optimizing space and reducing the number of individual items to transport. Many carriers offer discounted rates for pallet shipping, especially for large or bulky loads.

Maximizes Truck and Warehouse Space: Palletizing freight allows stacking and efficient storage, ensuring every inch of space is utilized in trucks and warehouses. This reduces the need for additional shipments, driving logistics cost savings and boosting operational efficiency.

Simplified Tracking and Inventory Management: Managing palletized freight is easier with fewer individual items to monitor. This minimizes errors, streamlines inventory management, and ensures more accurate freight tracking, improving the shipping experience.

Versatile Shipping for All Types of Freight: Pallet shipping is compatible with cargo types—from perishables to raw materials and consumer goods. Pallets come in wood, plastic, or metal materials, with configurations suited to specific freight needs.

Supply Chain Optimization: Pallets offer a standardized freight solution used across carriers and logistics providers, leading to faster transits, reduced delays, and seamless supply chain integration. This ensures timely deliveries and improves customer satisfaction.

Eco-Friendly and Sustainable Options: Many pallets are recyclable or reusable, making them a sustainable choice for businesses focused on green logistics. By using eco-friendly pallets, companies can reduce waste and align with environmentally conscious shipping practices.

These advantages demonstrate why palletized freight is ideal for businesses seeking secure, cost-efficient, and scalable shipping solutions. Optimize your operations by choosing pallet shipping services that ensure safe delivery, fast handling, and affordable rates.

Skid vs. Pallet: What’s the Difference?

When comparing skids vs. pallets in freight shipping, it’s essential to understand their distinctions and uses. While both serve as platforms for transporting goods, they differ in design, functionality, and application. Here’s a breakdown to help you decide which is better for your shipping needs.

What is a Pallet?

A pallet is a flat, stable structure with a top and bottom deck. Pallets are available in wood, plastic, or metal materials and feature two-way or four-way entry points for forklifts or pallet jacks. This design provides excellent stability for stacking and offers robust support for heavier goods, making pallets ideal for warehouse storage and freight shipping.

Key Features of Pallets:

- Top and bottom decks for better stability and weight distribution.

- It is ideal for heavy loads and stacking during transport and storage.

- They are commonly used in pallet shipping due to their compatibility with forklifts and pallet jacks.

What is a Skid?

A skid is a single-deck platform without a bottom deck, making it lighter and more mobile than a pallet. Skids are often used in temporary storage or to transport heavy machinery. They’re easier to drag or slide without a bottom deck, offering more flexibility for specific industrial applications.

Key Features of Skids:

- There is no bottom deck, making them lighter and easier to move.

- Often used for temporary storage or to support heavy, static equipment.

- They are less stable than pallets, making them unsuitable for stacking.

Skid vs. Pallet: Which Should You Use?

- Choose pallets for freight shipping, stacking, and long-term storage. Their two-deck design ensures excellent stability and makes them easier to handle with forklifts and pallet jacks.

- Choose skids for industrial applications or when transporting large, heavy items that don’t need stacking. Their lightweight design allows for easy movement on uneven surfaces.

Both skids and pallets have their place in logistics, but pallet shipping is the better option for freight transport due to its reliability, stability, and compatibility with modern supply chains.

Standard Pallet Dimensions and Sizes – A Complete Guide for Pallet Shipping

Understanding standard pallet dimensions is essential for optimizing your pallet shipping operations. Using the correct pallet size ensures your freight fits securely, maximizes space in trucks and containers, and complies with carrier requirements. Below, we cover the most common pallet sizes used in the U.S. and internationally to help you choose the right one for your shipping needs.

Standard Pallet Sizes in the U.S.

The most common pallet size in the United States is 48″ x 40″, also known as the GMA pallet (Grocery Manufacturers Association pallet). This standard size is widely used in freight shipping, warehousing, and retail.

- Dimensions: 48 inches x 40 inches

- Deck Boards: Typically, 3-4 top deck boards

- Weight Capacity: 2,500 lbs (dynamic load)

- Material: Wood or plastic

- Entry Points: 4-way entry for forklifts and pallet jacks

GMA pallets are favored because they fit seamlessly in standard trailers, making them ideal for cross-country shipping and supply chain logistics.

Other Common Pallet Sizes in North America

- 42″ x 42″ Pallet: Frequently used in the beverage industry.

- 48″ x 48″ Pallet: Often used for large containers and drums.

- 36″ x 36″ Pallet: Ideal for small or custom shipments.

These sizes are designed to meet the specific needs of different industries, from retail to industrial manufacturing.

International Pallet Sizes (ISO Pallets)

International shipping may require ISO-standard pallets, which vary by region. Here are some of the most commonly used sizes:

- Europe (EUR/EPAL): 1200 mm x 800 mm (47.2″ x 31.5″)

- Asia: 1100 mm x 1100 mm (43.3″ x 43.3″)

- Australia: 1165 mm x 1165 mm (45.9″ x 45.9″)

Using the correct pallet size ensures that your palletized freight aligns with international shipping standards and avoids customs or distribution center delays.

Choosing the Right Pallet Size for Shipping

- Domestic U.S. shipments: Use the standard 48″ x 40″ pallet for optimal efficiency.

- International shipments: Select the appropriate ISO pallet to comply with regional standards.

- Industry-specific needs: Choose from other common sizes for specialty products like 42″ x 42″ or 48″ x 48″.

Optimize Pallet Shipping with the Right Size

Choosing the correct pallet dimensions helps you:

- Maximize space utilization in trucks and containers.

- Reduce freight costs by avoiding oversized or underfilled pallets.

- Ensure smooth handling with forklifts and pallet jacks.

- Comply with shipping regulations for domestic and international transport.

How to Ship a Pallet: Step-By-Step Guide

The question of how to ship a pallet is most importantly answered through how you properly secure one for transit. A lot of damage can be sustained to a shipment because of improper bundling or securing of the freight. Below are the steps to how to ship a pallet successfully:

1. Package your Products On the Pallet Carefully.

- Choose a sturdy, undamaged box with the proper Edge Crush Test (ECT) rating for your box stacking needs. If the product is heavy, a double-sided corrugated may be best.

- Add ample cushion around the items.

- Fill space with proper padding.

2. Seal Each Container or Box

- Use a strong tape made of polypropylene that is the right thickness, depending on the weight of the items in your boxes.

- Tape with a 2.9 mil thickness should be used for boxes over 50 Ibs.

- Another option that is thicker and stronger than polypropylene tape is PVC-based tape.

3. Choose the Right Shipping Pallet

- Ensure the pallet is undamaged and no boards are missing or loose.

- Try to use a standard size 40″ x 48″

- A 4-way entry pallet is best as it’s easier to move with a forklift and pallet jack.

- Wooden pallets are cheap, affordable, and easy to repair. Plastic pallets are lightweight, durable, and resistant to moisture and pests. Metal pallets have the greatest strength and durability.

4. Load and Secure Your Pallets

- Make sure to align boxes perfectly when stacking to reduce loss of strength.

- Put the heaviest boxes at the bottom to avoid the shipment being top-heavy.

- Banding – Strapping made of steel and polyester is best for securing bundled loads to your pallet. Keep your bands close together to avoid damaging the bundled cargo, and use band cleats or strap protectors. Do not place strapping under the bottom deck of a pallet, as the strapping can be damaged when contacting a warehouse floor.

- Stretch Wrapping/Stretch Film – Stretch wrap provides complete coverage and keeps everything together. It will not offer protection to prevent damages. The more stretch wrap used, the better the pallet contains the product.

- Load Protectors – To protect your freight’s top and bottom layers, sandwich your freight between corrugated load protector pads. This will distribute the weight properly and keep the bottom boxes from slipping through the pallet slats.

- Edge Boards – Edge boards protect boxes’ edges, corners, bottoms, and tops. They help contain the load and stabilize it, protecting it from the friction caused by straps or banding.

5. Properly Labeling Freight for Transport

- When handling the freight, an address label should be visible to the forklift driver. Put the labels on the sides where the forklift entry is.

- Place an address label on each box or piece and number all boxes (x of x).

- FreightCenter recommends attaching a copy of our bill of lading to multiple sides of the shipment.

There are several types of pallets, with names based on their construction. Below are the most common pallets in shipping and a brief description of what separates them.

The choice of pallet/skid type depends on factors such as the specific application, load requirements, transportation methods, and industry regulations. Each pallet type has its advantages and limitations, so selecting the right pallet for your needs is essential to ensure efficient and cost-effective shipping and logistics operations.

Durable and cost-effective, wooden pallets provide secure support for all your freight. Ideal for stacking, storing, and smooth handling throughout the entire shipping process.

Perfect for sensitive and heavy freight, plastic pallets offer superior durability, weather resistance, and reusability. Optimize your pallet shipping with a cleaner, sustainable solution.

Designed for strength and longevity, metal pallets provide maximum support for heavy, industrial freight. Ideal for secure pallet shipping in demanding environments.

Lightweight, recyclable, and perfect for environmentally conscious businesses, paper pallets offer a green solution without sacrificing strength. Optimize your pallet shipping with sustainable choices.

Strong, lightweight, and resistant to moisture, plywood pallets are perfect for shipping delicate or custom freight. Enhance your pallet shipping with this durable and adaptable solution.

Engineered for durability and sustainability, pressed wood pallets are perfect for export and one-way shipping. Optimize your pallet shipping with this cost-effective, space-saving solution.

Built for heavy loads and easy handling, block pallets offer superior stability with 4-way forklift access. Maximize efficiency and security in your pallet shipping operations.

Designed for strength and affordability, stringer pallets are perfect for standard freight. Available with 2-way or notched 4-way entry, they streamline your pallet shipping process.

Perfect for retail environments, display pallets combine product visibility with easy handling. Optimize your pallet shipping and merchandising with these dual-purpose solutions.

Designed to stack within each other, nestable pallets save storage space and reduce return shipping costs. Enhance your pallet shipping with this lightweight, cost-effective solution.

With decks on both sides, reversible pallets offer enhanced durability and stacking versatility. Perfect for efficient pallet shipping and heavy-duty applications.

Certified for seamless cross-border logistics, Euro pallets offer durability and efficiency. Optimize your pallet shipping with these reliable, industry-standard solutions for global transport.

Tips to Load a Truck with Pallets

Loading a full truck of skids efficiently and safely involves several steps. Here are instructions to guide you through the process:

- Prepare the Truck: Ensure the truck is clean, in good condition, and has enough space for the number of skids you plan to load. Make sure the truck’s weight capacity is suitable for the anticipated load.

- Gather Necessary Equipment: Obtain equipment such as forklifts, skid jacks, and straps to aid in loading and securing the skids.

- Plan the Loading Sequence: Strategically plan how the skids will be loaded onto the truck. Consider the final destination, unloading requirements, and product stability.

- Organize Skids: Arrange the skids in a staging area close to the truck. Stably stack them, and inspect each pallet for stability, damage, or safety concerns. Do not load pallets that are damaged, weakened, or overloaded beyond their capacity.

- Load Skids: Use forklifts or pallet jacks to transfer the skids from the staging area onto the truck, starting with the back of the truck and working your way towards the front. Stack the pallets in a uniform and stable manner, ensuring that the weight is distributed evenly throughout the truck. Avoid stacking pallets too high or creating an unbalanced load.

- Secure the Load: As each skid layer is loaded, secure them using straps or load bars. This will prevent movement and shifting during transportation, enhancing safety and stability. Utilize any remaining gaps or empty spaces within the truck to optimize the load capacity. However, ensure that the load remains balanced and secure.

- Documentation and Labeling: Clearly label the truck with necessary information, such as the destination, load type, and any handling instructions. Ensure all required shipping documents are correctly completed.

Once your skids are packed, labeled, and measured, you can get a FreightCenter quote. With their expertise, they help select the right pallet size, advise how to arrange loads securely and provide necessary protections. Our extensive carrier network ensures cost-effective solutions and reliable delivery, giving you peace of mind throughout transportation. Trust FreightCenter to streamline your shipping operations and deliver your goods with confidence.

Pallet Shipping FAQ

Q. What is pallet shipping?

Pallet shipping is a method of transporting goods by securing them on pallets, which are flat platforms made of wood, plastic, or metal. It ensures easy handling, stable storage, and safe transportation of multiple packages.

Q. How much does it cost to ship a pallet?

The cost of pallet shipping varies based on the weight, dimensions, distance, and freight class. On average, domestic LTL pallet shipping ranges from $150 to $300 per pallet, while international shipping can cost $500 or more.

Q. What are the standard pallet dimensions?

The most common or standard pallet size in the U.S. is 48″ x 40″. International sizes vary, with 1200 mm x 800 mm being standard in Europe. Choosing the right size ensures better space utilization and smoother shipping.

Q. What is the maximum weight a pallet can hold?

A standard wood pallet can hold up to 2,500 lbs of dynamic load (in transit). Plastic or metal pallets can support even more weight, making them ideal for heavy-duty shipments.

Q. What types of pallets are used in pallet shipping?

The most common pallet types include:

- Wood pallets – Affordable and versatile

- Plastic pallets – Lightweight and durable

- Metal pallets – Heavy-duty for industrial shipments

- Euro pallets – Standardized for international shipping

Q. How do I secure my items on a pallet for shipping?

To secure your freight, stack items evenly, wrap them tightly with stretch wrap, and use straps or bands for extra stability. Avoid overhanging items to prevent damage.

Q. What is the difference between LTL and FTL pallet shipping?

- LTL (Less-than-Truckload): Multiple shipments from different shippers share space on a truck. It’s cost-effective for smaller loads.

- FTL (Full Truckload): A single shipper uses the entire truck space, which is ideal for large or urgent shipments.

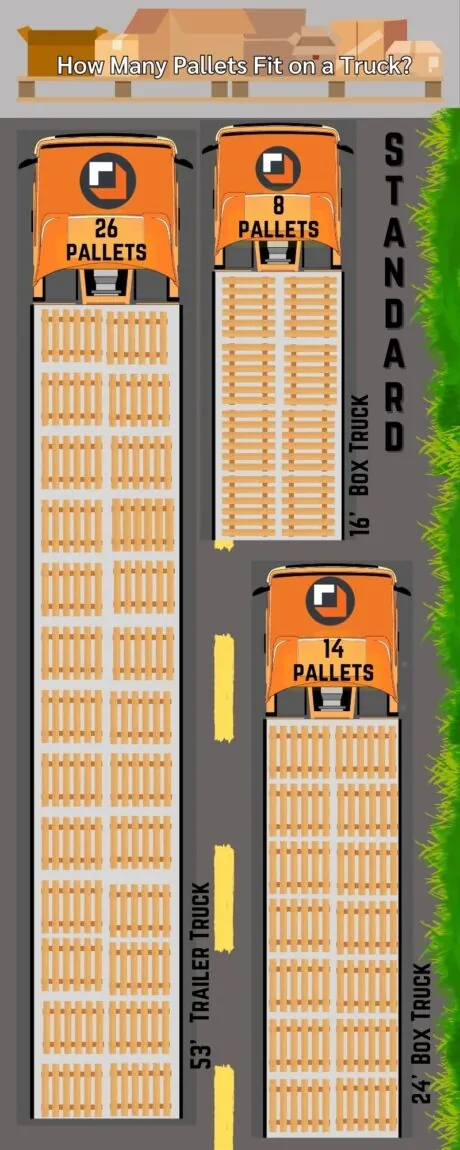

Q. How many pallets fit on a truck?

A standard 53-foot truck can fit 26 standard 48″ x 40″ pallets when loaded single-stacked. Double-stacking pallets may allow for up to 52 pallets, depending on height and weight.

Q. Do I need special equipment to ship pallets?

If you don’t have a loading dock, you may need a liftgate service to load or unload. Forklifts or pallet jacks are also used to handle palletized freight.

Q. Can I ship pallets internationally?

Yes, pallets are widely used in international freight shipping. However, wood pallets must comply with ISPM-15 standards (heat-treated) to prevent the spread of pests.

Q. What is the best way to reduce pallet shipping costs?

To save on pallet shipping costs:

- Use standard-sized pallets to avoid dimensional fees.

- Consolidate multiple packages into fewer pallets.

- Compare LTL and FTL rates to find the most economical option.

- Use freight brokers to access competitive rates.

Q. 12. How long does pallet shipping take?

The transit time depends on the distance and carrier. Domestic pallet shipping generally takes 1-5 business days, while international shipments may take 7-14 days or more.

Q. 13. What should I do if my pallet shipment is damaged?

If your pallet shipment is damaged, inspect the goods immediately and take photos. Contact the carrier to file a claim with supporting documentation, including the bill of lading (BOL) and photos.

Q. 14. How do I get a pallet shipping quote?

For an accurate quote, provide the pallet’s weight, dimensions, pickup and delivery locations, and any special services required (e.g., liftgate or residential delivery). Many carriers offer instant online quotes.

Q. What industries use pallet shipping?

Pallet shipping is essential across multiple industries, including:

- E-commerce for shipping bulk products

- Manufacturing for moving raw materials

- Food and beverage for transporting perishables

- Retail and wholesale for distributing inventory

Q. What are freight classes, and why do they matter for pallet shipping?

Freight classes are used to categorize shipments based on density, value, and handling requirements. A higher freight class means higher shipping costs. Choosing the correct class helps prevent delays and unexpected fees.

Q. Can I track my pallet shipment?

Yes, most carriers offer real-time tracking for palletized freight. Tracking updates the shipment’s status, location, and estimated delivery time.

Q. Are there eco-friendly pallet options?

Yes, plastic and paper pallets are sustainable alternatives to wood pallets. They are reusable, recyclable, and ideal for businesses focused on green logistics.

Q. Can pallets be reused?

Many pallets, especially plastic or metal, are reusable for multiple shipments. Wood pallets can also be repaired and reused, contributing to sustainable shipping practices.

Q. Is pallet insurance necessary?

For high-value shipments, it’s recommended to purchase cargo insurance to protect against loss or damage. Some carriers offer limited liability coverage, but additional insurance ensures complete protection.

How Pallet Shipping with FreightCenter Can Help Businesses Improve Efficiency

Instant Quotes

Partnering with FreightCenter for pallet shipping allows businesses to streamline their logistics operations by accessing a wide network of carriers and competitive rates. FreightCenter simplifies the process of booking, tracking, and managing shipments, ensuring businesses save both time and money. With access to instant quotes and multiple carrier options, companies can quickly select the most cost-effective and efficient shipping solution for their specific needs.

Advanced Technology Platform

By utilizing FreightCenter’s advanced technology platform, businesses can better coordinate their pallet shipments with features such as real-time tracking and automated freight management tools. These tools improve visibility and reduce the risk of delays or lost shipments, allowing companies to stay on top of their logistics from origin to destination. This seamless integration of technology ensures that companies not only meet tight deadlines but also maintain better control over their supply chain.

Expert Customer Support

FreightCenter also offers expert customer support to assist with freight class identification, claims, and any special shipping requirements, such as liftgate services or international compliance. This hands-on support reduces operational burdens and ensures smooth shipping processes, allowing businesses to focus more on core operations. With FreightCenter’s pallet shipping solutions, companies can increase efficiency, lower shipping costs, and enhance overall customer satisfaction by delivering goods safely and on time.