What is Air Ride Suspension?

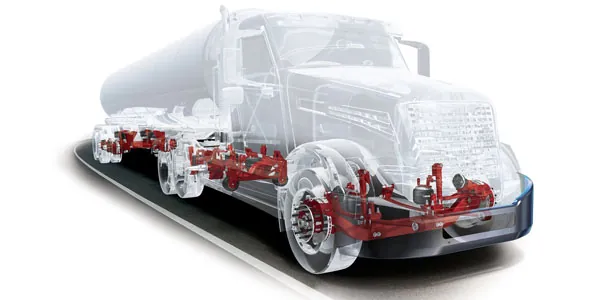

Air ride suspension provides a smooth, comfortable ride for both truck drivers and your freight. Learn more about air ride suspension systems and why freight trucks implement them to protect your shipments.

What is an Air Ride Suspension?

An air ride suspension is a sophisticated suspension system powered by an air compressor. Acting as the spine of the vehicle, suspensions support the load being hauled and absorb impacts made from driving on unstable roads, ensuring a smoother ride. Unlike traditional suspension systems, air ride suspensions use compressed air to cushion the vehicle’s axle from road disturbances. Air rides are used in 75 to 80% of semi trucks, becoming standard for long-haul trucking for their superior load capability, reduced maintenance needs, and enhanced ride comfort. This technology ensures freight is well-protected and secure during transit and provides a comfortable ride for the truck driver.

Thousands of businesses trust FreightCenter to move their freight faster, smarter, and cheaper! From unbeatable rates to top-notch service, our customers are raving about their shipping success.

See why they keep coming back!

Award-Winning Service, Trusted by Shippers Everywhere!

- 2021, 2017 & 2016 Food Logistics’ Top Green Providers

- 2021 & 2018 Supply & Demand Chain Executives’ Pros to Know: Matthew Brosious

- 2020 & 2019 Top Food Logistics’ 3PL & Cold Storage Provider Award

- 2020 & 2019 Business Observer’s Top 500 Companies on the Gulf Coast

- 2020 & 2017 SmartWay® Transport Partner

- 2020 & 2017 Food Logistics’ Champions: Rock Stars of the Supply Chain

- 2020 Best of Palm Harbor Awards for Local Businesses

- 2017 Green Supply Chain Award from Supply & Demand Chain Executive

- 2017 Tampa Bay Business Journal Heroes at Work

- 2016, 2015, & 2012 Food Logistics Top 100 Software and Technology Providers

- 2013 Tampa Bay Business 100 by Tampa Bay Business Journal

- 2013 Top 100 Great Supply Chain Partners by SupplyChainBrain

- 2012 TIA Samaritan Award Honorable Mention

- 2012, 2011 & 2010 TBBJ Fast 50 Recipient

- 2013, 2011, & 2010 Diversity Business Top Businesses

How Does Air Ride Suspension Work?

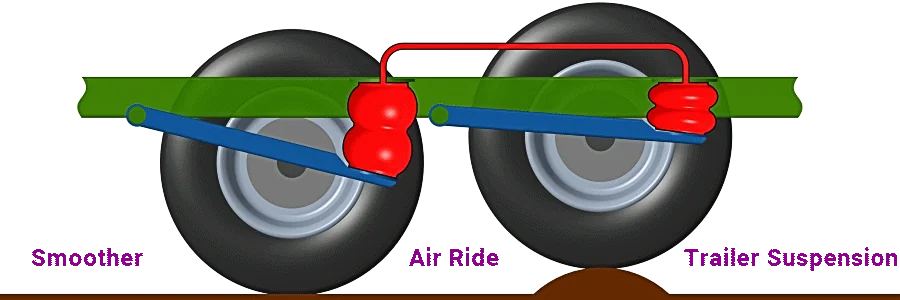

Air ride suspensions consist mainly of airbags (or air springs), valves, and an air compressor. The compressor pumps compressed air into the rubber airbags, inflating them to lift the chassis from the axle and tires. This setup prevents road impacts from affecting the trailer. An Electronic Control Air Suspension (ECAS) system monitors and adjusts the air pressure in the airbags to maintain optimal ride height and smoothness.

As the truck moves, the independent wheel movement provided by the air ride suspension system minimizes road shock and maintains consistent wheel height, effectively cushioning the ride. This keeps the truck’s cab from shaking too much and increases the life expectancy of the wheels, axle, and chassis. Trailers with air ride suspensions can also lift or lower themselves at loading docks, keeping the trailer level.

Air Ride vs. Leaf Spring Suspension

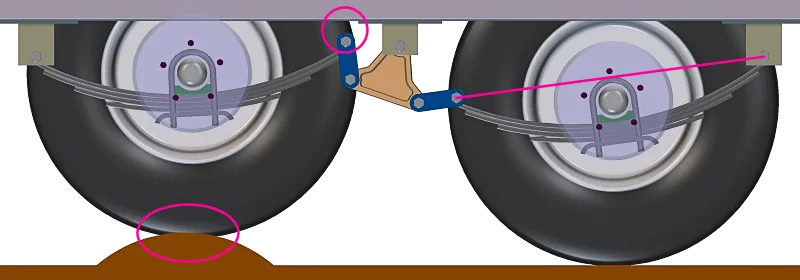

While air ride suspensions are popular, so are leaf spring suspensions. These systems were the earliest type of suspension developed and, for a while, one of the only ones available for all vehicle types until other systems like the air rides became popular. They use long, layered, flexible steel strips to form a spring. The springs are attached to the trailer frame, which compress and absorb impact as the truck moves. The amount of support the leaf spring suspension provides is proportional to the number of leaf springs used.

Here are some comparisons between air ride and leaf spring suspensions:

- Design Complexity: Leaf springs are simpler, whereas air rides involve intricate components like valves and ECAS.

- Weight and Fuel Efficiency: Air rides are heavier, potentially reducing fuel efficiency compared to leaf springs.

- Maintenance: Leaf springs require more frequent maintenance due to their mechanical nature. Air rides, although generally needing less frequent maintenance, can incur higher costs if airbags leak or another part is broken.

- Ride Comfort: Air rides offer superior comfort, particularly on uneven terrain. While leaf springs do provide comfort, truck drivers claim trucks with leaf springs make the cab buck and shake on the road.

- Cost: Air rides are more expensive initially but offer long-term savings due to lower maintenance needs. Leaf springs are more affordable upfront but may require more upkeep.

Frequently Asked Questions About Air Ride Suspensions

Q. What is an air ride suspension?

An air ride is a type of suspension system attached to a vehicle. Suspension systems support a truck’s trailer load while providing a smoother riding experience. The air ride uses compressed air inside airbags, valves, and other complex parts to protect the truck from rough roads and other disturbances while driving.

Q. What’s the difference between an air ride and a leaf spring suspension?

An air ride suspension utilizes compressed air, airbags, and valves as part of its system. In contrast, leaf springs use flexible steel pieces to act as cushions attached to a steel suspension system. Both suspensions offer support and protection for trailer loads, but air rides provide superior protection, are more comfortable for the driver, and require less maintenance than leaf springs. However, air rides are more complex in design, heavier, and more expensive upfront than leaf springs.

Q. How are air ride suspensions related to freight shipping?

Air ride suspensions are the standard suspension systems in heavy-duty, long-haul trucks. They smooth out the ride while shielding the trailer from sudden shakes and bumps along the road. This helps with protecting the cargo inside the trailer, including fragile items.

Q. How can I find out if a carrier uses trucks equipped with air ride suspensions?

The best way to determine what carriers have air ride suspension systems attached to their fleet of trucks is to contact the carrier. They will provide you with information about their truck’s specifications as best they can. A freight broker can also find out for you if asked.