Crating and transporting heavy machinery requires a comprehensive understanding of best practices and safety considerations to protect the individual and the equipment involved. Extra care must be taken to ensure the machinery’s integrity and safety, from crating to transport. Proper crating is critical to minimizing risks and providing a secure journey from Point A to B. Luckily, paying attention to essential details such as appropriate crate design, proper crating practices, and documentation, along with safety regulation compliance, can help alleviate potential safety threats to both the individual and the heavy machinery shipment.

Table of Contents:

● First Steps

● Crating Process

● Documentation

● Common Risks

● Tools Maximizing Safety

● Future Trends and Technologies

● Significance

Heavy machinery or equipment is designed to handle heavy-duty tasks and is commonly used in industries such as forestry, agriculture, mining, and construction. Some common examples of heavy machinery include bulldozers, excavators, loaders, cranes, and forklifts. It’s hard to imagine that such hefty pieces of equipment are packaged and shipped successfully worldwide. Crating plays a significant role in the success of the shipment, which relies on proper practices to prevent damages that ultimately result in costly repairs and project delays.

Well-designed crates are imperative, as they act as a protective shield for the machinery. The crates help protect the equipment from external forces and temperature fluctuations and distribute weight evenly, preventing imbalances during shipment. Appropriate crate design needs to account for factors such as weight, dimensions, fragility, and transportation. Before you begin the crating process, consult the handling guides issued by the manufacturer for best practices.

First Steps

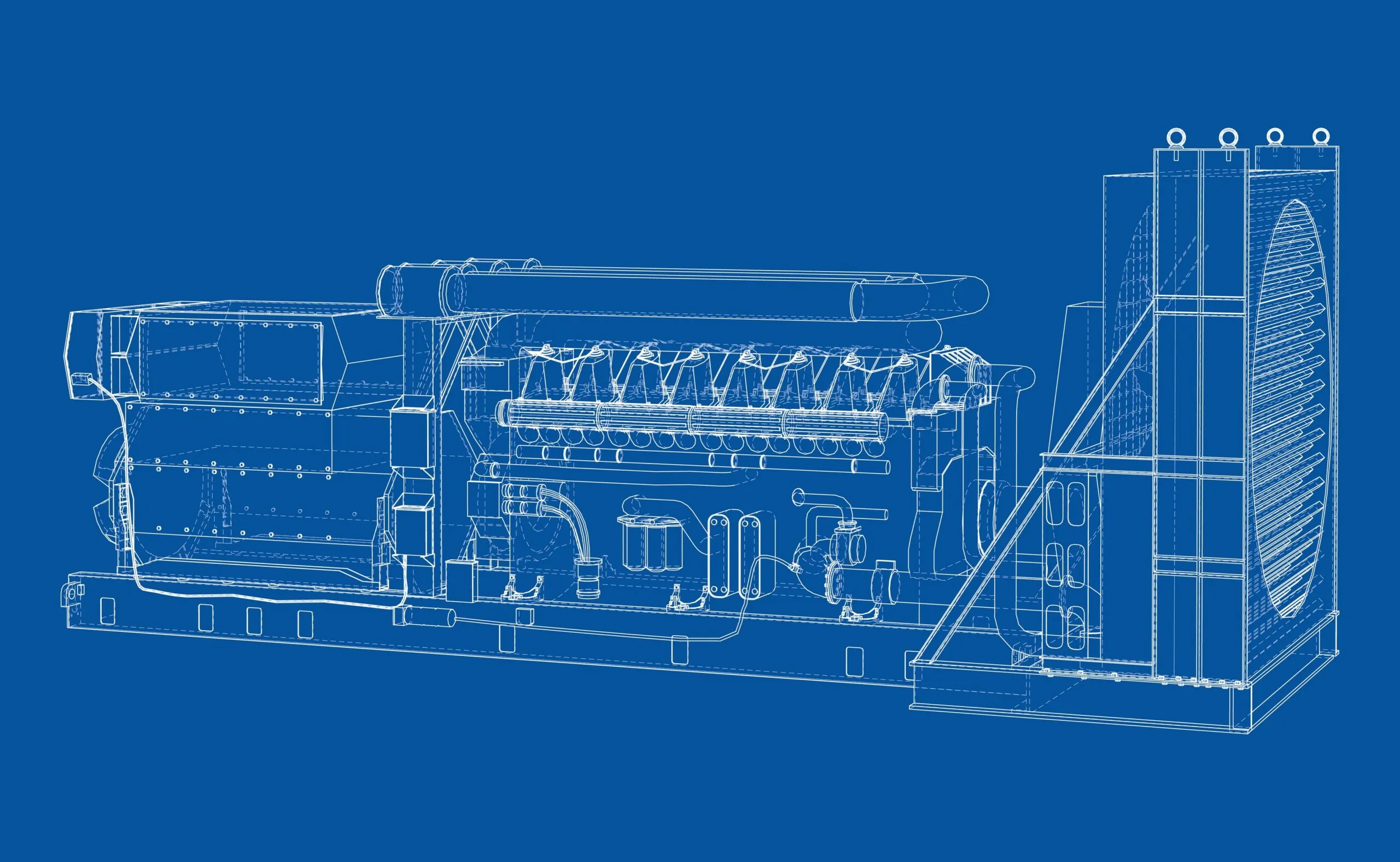

Now that you understand the importance of crating your heavy machinery, the first step in the process is to obtain the proper dimensions, measurements, and weight of the shipment. It is crucial to understand if certain equipment parts are heavier than others to plan for effective weight distribution in the crating design. If it is impossible to see machinery in person, providing photos, CAD drawings with specifications, and other helpful visuals is critical. Machinery needs to be thoroughly inspected before crating and before the shipping process. Inspections will help detect any deterioration, wear, or already existing issues.

These measurements will help determine the size, strength, and construction materials needed for the crate. It is also essential to consider any fragile components or sensitive electronics that require additional protection in the crating process. These delicate or sensitive components may include sensors, control panels, and precision parts, so take extra precautions to secure and protect them.

Heavy machinery often requires specialty custom crating services due to its oddly shaped, heavy, oversized, and fragile nature. The design of the custom crating should account for all the machinery’s unique requirements, using the same critical factors such as weight, dimensions, fragility, transportation mode, and special handling requirements.

Crating Heavy Machinery Process

Be sure to use high-quality materials, such as plywood and hardwood, that can withstand the machinery’s weight while providing adequate protection. Do not use low-quality materials, which will compromise the crate’s structural integrity. The crate must withstand any external factor involved in transportation, so reinforce the edges with additional bracing to protect against shifting and potential impacts.

Another critical aspect to remember in the design process is to design for accessibility, which allows for easy loading and unloading, such as removable panels or access points. Accessibility is crucial for inspections or repairs needed during the transit process. Proper ventilation is another essential component of the crating process. Ventilation helps prevent moisture buildup, often leading to corrosion and damage, especially in sensitive components. These risks can be mitigated by creating ventilation holes and incorporating moisture-resistant materials.

After the crate is constructed, the machinery must be adequately secured to prevent movement and shifting during transportation. Appropriate strapping, padding, and blocking techniques should be used for stability. Shock-absorbing materials like foam and rubber should also be considered to minimize the impact of vibrations. Protective materials like foam or bubble wrap can protect fragile parts before taping or using other fasteners, helping to prevent shocks and vibrations during transit. Shrink wrap is another option for ensuring additional security and will protect machines from dust and moisture.

Documentation

Lastly, one of the most critical aspects of the crating and shipping process is proper documentation, labeling, and compliance with safety regulations. Crates must be labeled with machinery weight, name, and other handling instructions. Proper labeling and documentation allow handlers to identify and handle the crate with adequate care. Photographs are another vital aspect of appropriate documentation, which helps to document the condition of the machinery before and after transit. Shipping manifests, certificates, customs documents, and maintenance records are just a few of the essential documentation requirements.

Label the crate with information such as the machinery name, model number, and serial number, among other unique identifiers. This helps identify the machinery and match it with the correct documentation. Instructions should explain how to handle the crate, which side should be up, specific lifting points, and precautions. “Fragile” and “Handle with Care” labels must be displayed to alert handlers; weight and dimensions should also be included on the exterior. The crating process must comply with all industry safety regulations and standards. Familiarize yourself with all local, national, and international transportation regulations. This step is critical in avoiding legal trouble and must not be overlooked.

Common Risks

Transporting heavy machinery and equipment requires professional logistics, engineering, and design expertise/experience. Skidding, lifting, and moving crates all must be done carefully and methodically to minimize risks and damages.

Insufficient load securement: It is critical to ensure machinery is secured correctly using tools such as straps, chains, and tie-downs. Follow load securement rules set forth by the (DOT) and Federal Motor Carrier Safety Administration. This step will help prevent machinery shifting or movement during transportation, which can lead to dangerous consequences.

Improper handling and lifting: Mishandling of machinery can lead to accidents, injuries, and damage. Personnel must be trained on proper lifting techniques, have access to PPE, and have crates marked with instructions for safe handling and lifting.

Inadequate protection from elements: Weather can damage machinery, so proper care should be taken to ensure it is enclosed correctly, crated, and wrapped. Crates should protect the machinery from dust, moisture, and other factors.

Insufficient equipment support: Consider partnering with certified specialty crating companies to design and build custom pallets, crates, or skids that will support the dimensions, size, and weight of the machinery.

Lack of proper maintenance: Regular machinery maintenance is essential to prevent issues during transportation and later. Make sure machinery works well before crating it, and repair or replace any worn or faulty parts to help minimize damage risks.

Tools Maximizing Safety

Steel-toed shoes: Personnel should wear these protective shoes to protect their feet from falling objects and other workplace hazards.

Ear protection: Ear muffs and ear plugs should also be worn to reduce noise exposure from loud machines and protect against hearing loss and damage.

Proper lighting: Keeping the workplace well-lit is crucial to improving visibility and reducing the risks of accidents and errors.

Adequate PPE: Workers should wear personal protective equipment, including gloves and safety glasses, to protect them from hazards during crating.

Regular Training: Proper training is critical for personnel, and regular training sessions should be conducted for proper lifting techniques, safe handling practices, and equipment use.

Partnering with Certified Crating Companies: Partnering with certified trading companies with expertise in handling heavy machinery can provide the proper guidance and expertise to ensure the crating process meets all safety standards and regulatory requirements.

Future Trends and Technologies

Sustainability: The heavy machinery industry has increased its focus on sustainability by adopting electric equipment and technologies that promote energy efficiency and reduce emissions.

IoT: Manufacturers of heavy machinery are transforming the industry by incorporating technologies such as AI, IoT, and ML. These technologies help enhance performance, reduce human error, and optimize operational efficiency.

Safety Focus: Safety has become a top priority for manufacturers, implementing safety features and technology to minimize risks.

Electric and Hybrid Power: The industry also incorporates electric and hybrid systems. This electric equipment is being developed as a more sustainable alternative to diesel power.

Significance

Proper crating ensures safe transportation and increases customer satisfaction. Following best practices and prioritizing all safety considerations is critical. Doing so helps protect valuable assets from damage, reduce delays, and adhere to safety protocols. The effect is reduced downtime, increased customer satisfaction, and enhanced reputation within the industry. Most importantly, you will be able to sleep better at night knowing that you took all precautions to ensure safety.

Researching the crating process and what is required is very beneficial, especially if you have never shipped heavy machinery. Sullivan Industrial is here to help you understand the crating process and any regulations or requirements. We will help you create a shipping strategy that guarantees safety and success.